Custom Patterned Stand Up Pouches | Premium Resealable Snack Food Packaging

- Note: Prices shown are for reference (Standard Configuration). Final cost depends on your specific size, material, and printing complexity. Please Request a Quote for an accurate total.

Get Factory Direct Pricing or Free Samples

Product Compliance: ✅ ISO9001 · ✅ ISO14001 · ✅FSC · ✅Sedex · ✅BSCI

🔒 Your information is safe with us. Non-Disclosure Agreement (NDA) Available.

Related Products

Custom Engine Oil Spout Pouches | Premium Automotive Fluid Packaging with Handle

Custom Printed Stand-Up Pouches with Zipper | Resealable Food Packaging Bags | Wholesale Private Label Doypacks

Custom Printed Candy Pouches | Vibrant Stand Up Bags with Hanging Hole

Custom Printed Spout Pouches | Liquid Packaging Stand-Up Bags with Nozzle | OEM Refill Packs Wholesale

Custom Liquid Concentrate Pouches | Premium Beverage Packaging with Handle

Products Description

| Printing | |

|---|---|

| Material |

Customized |

| Thickness |

Customized |

| MOQ |

3000 |

Custom Patterned Stand Up Pouches | Premium Resealable Snack Food Packaging

Elevate your snack food packaging with our premium customizable stand-up pouches that combine eye-catching pattern designs with practical functionality. These sophisticated bags are specifically engineered for specialty snack foods, featuring a distinctive clear window panel that showcases your product while maintaining freshness and appeal. Each pouch incorporates high-quality printing capabilities that allow for intricate pattern designs across the entire surface area.

Our stand-up pouches utilize advanced printing technology that ensures crisp, vibrant pattern reproduction and consistent color matching throughout your production run. The innovative three-layer film structure provides superior barrier properties against moisture and oxygen, while the resealable zipper closure system ensures product freshness after opening. The clear front panel window can be customized in size and shape to create the perfect product presentation.

These versatile packages are available in sizes ranging from 100g to 1kg, making them ideal for various snack portions and product types. The durable bottom gusset provides stable shelf presence, while the high-quality laminated structure offers excellent puncture resistance and shelf life protection. Custom features can include metallic finishes, matte or glossy lamination, and special effect printing to enhance your brand’s visual appeal.

The pouches are manufactured using food-grade materials that meet FDA standards and undergo rigorous quality testing to ensure consistency in both appearance and performance. The premium printing process allows for seamless pattern repetition, gradient effects, and precise color matching to maintain brand consistency. Whether you’re packaging gourmet popcorn, specialty snacks, or artisanal treats, our patterned pouches provide the perfect balance of visual appeal and practical functionality.

Every aspect of the pouch can be customized to your specifications, from the pattern design and window placement to zipper color and interior barrier properties. Our experienced packaging team provides comprehensive support throughout the design process, ensuring your final product perfectly aligns with your brand vision. Contact us today to discuss your custom requirements and receive detailed pricing options for your unique packaging needs.

How to Make an Order

The extremely simple ordering process makes it easy for you to order printed products

1. Find Product

2. Graphic Design

3. Inquiry and Pay

4. Sample Assessment

5. Final Delivery

Design Guidelines for Perfect Printing

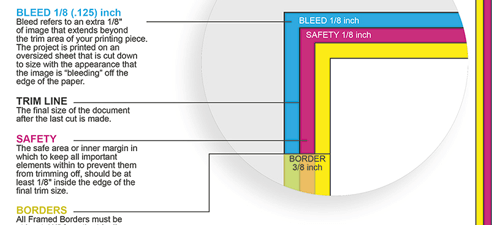

Size and Bleed Guidelines

Understand the difference between finished product size and bleed size. The finished product size is the final size of your item, typically 1-3mm smaller than your digital file on all sides. The bleed is an extra margin reserved for cutting: 3mm for printed products like cups, bags, or packaging pouch. Keep important elements at least 0.25 inches from the edges to avoid trimming, and we will provide precise dimensions in the final artwork.

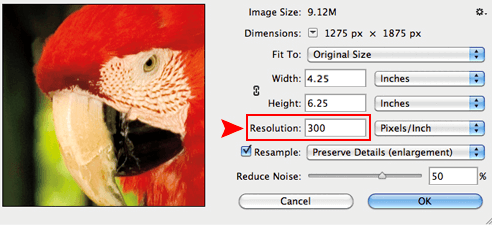

File Requirements

Ensure your custom design meets our printing requirements for the best results. Use vector files created in professional software like Adobe InDesign, CorelDRAW, or Illustrator to guarantee sharp text and graphics. If using Photoshop, maintain a resolution of at least 300 DPI. For images within your design, ensure high clarity to avoid pixelation. Upload files in JPG, PNG, or PDF format, with a maximum size of 10MB.

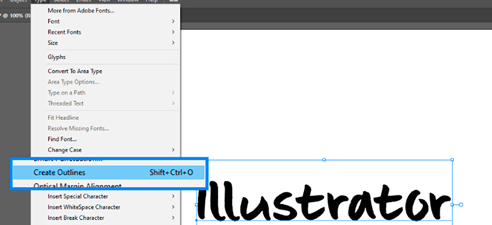

Text and Color Preparation

Convert all text to curves (or outlines) to prevent font issues. This ensures special fonts in your design don’t get lost or altered when opened on different systems, preserving the overall look of your artwork. Use CMYK color mode for accurate printing results.

Notes

About color difference

Color differences may arise between your digital artwork and the printed product due to variations in monitors, printers, or materials like paper or plastic. We use CMYK color mode to ensure accurate color reproduction, but slight deviations are normal in printing. To achieve the best match, provide files in CMYK.

About Sampling

Request a physical sample to verify your design’s appearance on the final product. Sampling costs $100 per color per product, ensuring you can review color accuracy, material texture, and print quality before bulk production.

Samples help ensure your customized products meet your expectations.

Warm Tips:

For the best color accuracy, please refer to a printed color chart or Pantone color guide when preparing your artwork. Due to variations in monitors, materials, and printing processes, a color difference of up to ±5% is normal and within industry standards.

Only logged in customers who have purchased this product may leave a review.

Reviews

Clear filtersThere are no reviews yet.